Ngwaahịa

-

Mmanụ ala na ihe mgbakwunye maka mmanụ na-atụgharị

Ester pụrụ iche na-ebelata esemokwu dị na mpaghara rlling seam ma hụ na ịdị ọcha nke mgbakasị ahụ.

Belata ntụ ntụ na iyi nke elu igwe, gbochie ihe siri ike n'elu.

Ester mgbagwoju anya na-enye mmanu mmanu.

Ebe ọrụ ka mma.Obere mkpọtụ, obere ujo, belata oriri, chekwaa ike, belata ọnụ ahịa echekwara yana ogologo ndụ ọrụ -

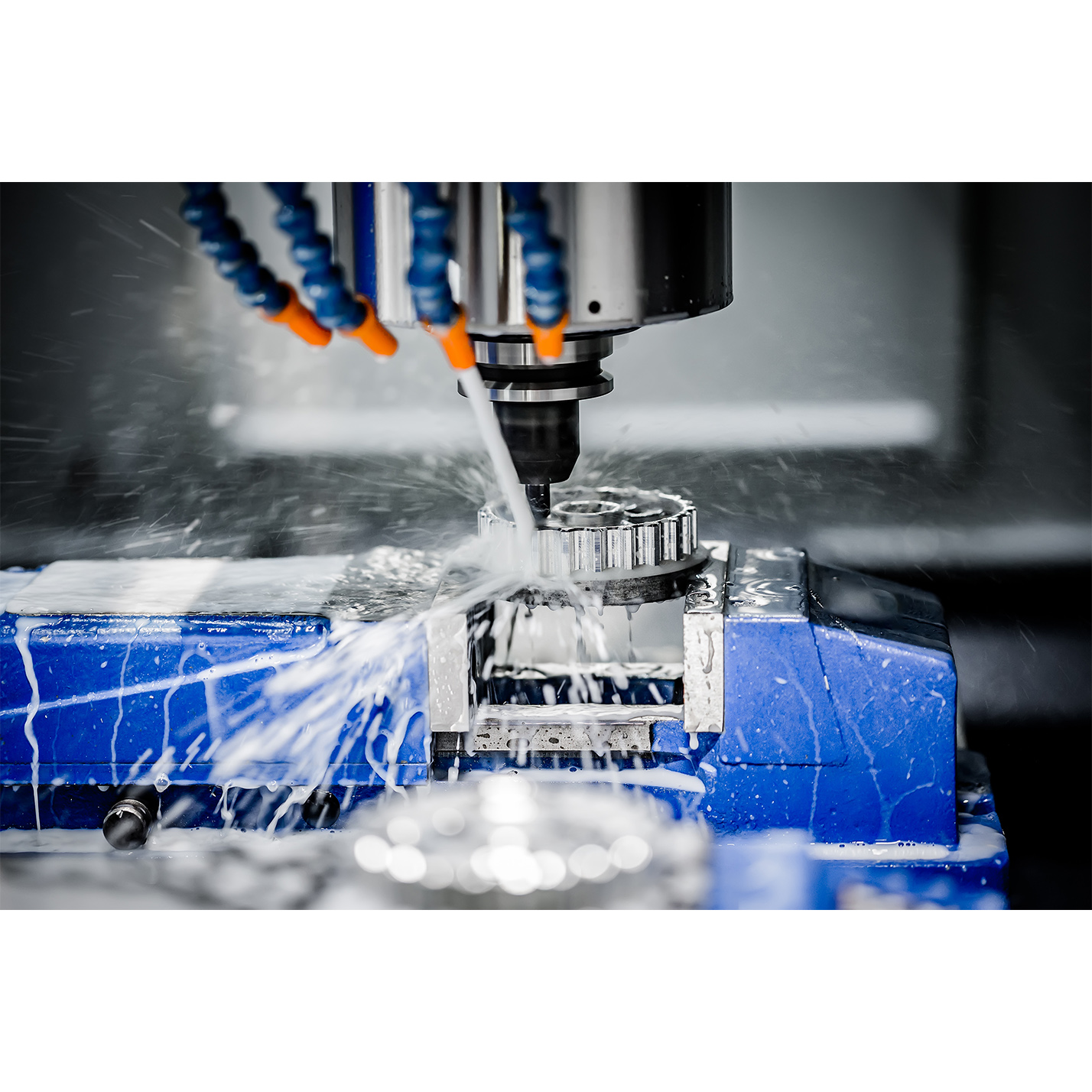

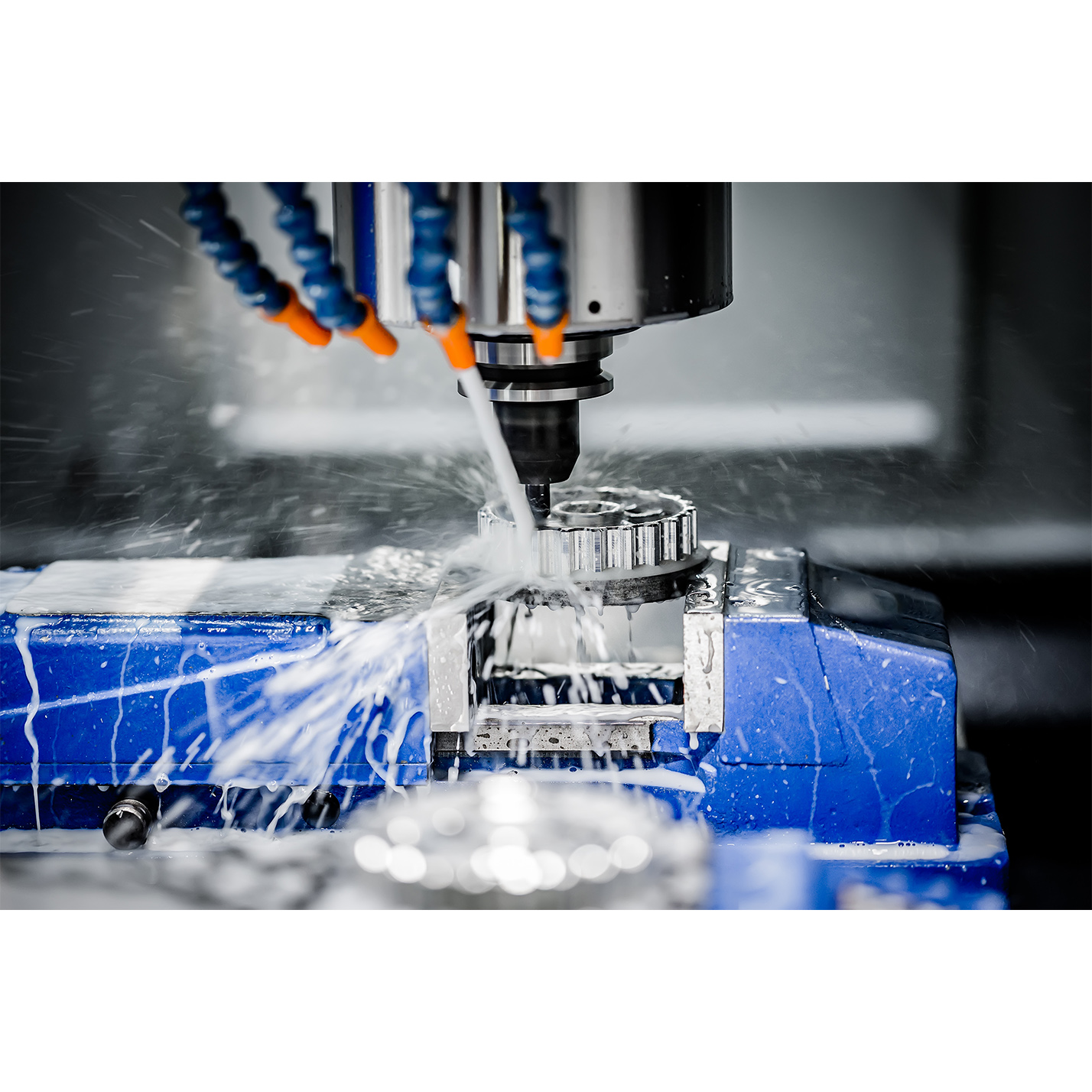

Ihe mgbakwunye mmanu maka igwe na-arụ ọrụ igwe

Ester Series maka igwe na-arụ ọrụ igwe:

Monoesters, diesters na polyol esters nke fatty acids eji na mmanụ ala metal na-arụ ọrụ mmiri iji belata esemokwu elu

n'etiti mmanụ na metal, na-enye ezigbo seepage ike.Maka mmiri mmiri na-arụ ọrụ igwe na-arụ ọrụ mmiri, ọ na-eji maka igbari mmanụ ma weta EP na corrosion remover.

Ihe mgbakwunye mmanụ maka injin:

Esters polymeric pụrụ iche nwere ihe nrụpụta ihe nkiri mara mma na-enye injin na nnyefe mmanụ na-emeziwanye arụmọrụ.

-

Mgbakwunye mmanụ na-arụ ọrụ ígwè

PAG quenching usoro:

Mmiri viscosity dị elu PAG soluble, na-achịkwa usoro ntụ oyi site n'ịgbanwe oke molar na itinye uche nke polymer.

Mmiri mmiri doro anya na ngwaahịa agba ọkụ na-eme ka o doo anya na ngwaahịa ikpeazụ.

Ngwongwo nhicha dị mma, dị mma iji hichaa workpiece mgbe emechara.

Mgbakwunye mmanụ na-emenyụ ọkụ:Polymer dị elu na-enye ọmarịcha ihe nchapụta nke arụrụ arụ ọrụ.

Mmiri viscous transperent, ọ dịghị mkpa kpo oku, dị mfe iji.

Ebe dị elu, ndụ ogologo, obere usoro onunu ogwu, adabara mmanụ na-egbuke egbuke, mmanụ na-eme ka ọ dị ngwa ngwa, na-atụ aro pụrụ iche iji na mmanụ quenching isothermal. -

Mmanụ ala maka injin ụgbọ ala na nnyefe

PAG maka injin ụgbọ ala na nnyefe

Dị ka ntọala mmanụ sịntetik, PAG nwere mgbasa ozi pụtara ìhè, ịdị ọcha nke na-enye nkwụsi ike dị elu nke okpomọkụ, mmanu na mmiri ọkụ dị ala.

Ọnụọgụ esemokwu dị ala nwere ike melite akụ na ụba mmanụ ọkụ ma chebe esemokwu nke ọma.

Ester sịntetik maka injin ụgbọ ala na nnyefeKpamkpam esterification polyol ester na diesters, ịdị ọcha dị elu.

Igbari abụba mmanụ ịnweta mmanụ na PAO n'okpuru okpomọkụ dị elu, belata nkwụnye ego na ihe nkiri.

Nnukwu viscosity dị ala nke CCS nwere ike melite ikike mmalite na obere okpomọkụ.

Nkwụsi ike mgbochi oxidation pụtara ìhè yana mgbasasa dị ọcha na-eweta ogologo ndụ ọrụ. -

Mmanụ ala maka Grease

Mmanụ ala maka griiz:

Ester dị ọcha, ezigbo mmanu na solubility

Enwere ike imebi ihe na mmeghari ohuru, zute ọkọlọtọ kọntaktị nri

N'ịbụ ndị na-enwe oke okpomọkụ, mee ka ikuku evaporation dị ala na okpomọkụ dị elu ma ghara ifriizi na obere okpomọkụ

Enwere ike iji PAG dị iche iche dị ka mmanụ griiz dị ala iji kwalite mmanu na akụrụngwa okpomọkụ dị ala. -

Mmanụ ala maka oke ọkụ yinye mmanụ

PAG maka mmanu yinye okpomọkụ dị elu:

Kwesịrị ekwesị okpomọkụ nwere ike iru 220 ℃, n'ọtụtụ ebe na ụgbọala ụlọ ọrụ.

Esters sịntetik maka mmanụ yinye okpomọkụ dị elu:Jiri dipentyl alcohol ester na polybasic acid ester dị ka mmanụ isi, ejiri n'etiti 250-300 ℃.